(E) (2) Dedicated Equipment Space Outdoors Code Change Summary The dedicated equipment space requirements for certain outdoor equipment has been reworked into a list format and an exception was added Switchboards, switchgear, panelboards, and motor control centers have specific dedicated equipment space requirementsThe purpose for the National Electrical Code is to provide a safe installation, but Article 110 is perhaps focused a little more on providing an installation that is safe for the installer and maintenance electrician, so time spent inAnalysis Section (A) (3) describes the height of the working space and allows for electrical equipment to intrude into the working space for a maximum depth of 6" This can often be seen in equipment rooms that have a wireway protruding outward above or below a panelboard

Sample Pages

Nec 110.26 working space

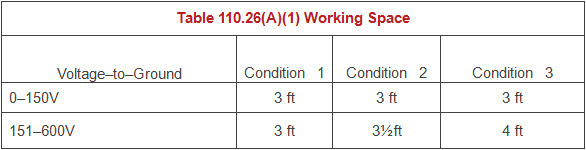

Nec 110.26 working space-Section of the National Electrical Code (NEC) requires specific minimums for working space around electrical equipment Section is divided into six subsections, and some of them contain even more subsectionsSpaces About Electrical Equipment Access and working space are required around all electrical equipment to allow safe operation and maintenance (A) Working Space Equipment likely to require examination, adjustment, servicing, or maintenance while energized must have working space in accordance with (A)(1) through (A)(4)

Http Www Teces Org Docs 12 Pdf

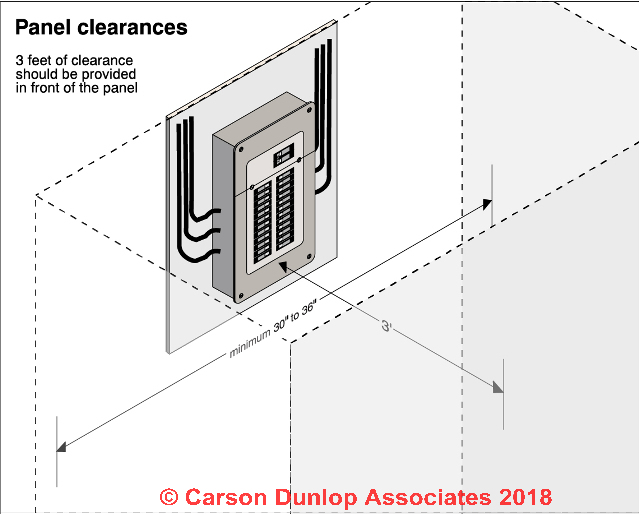

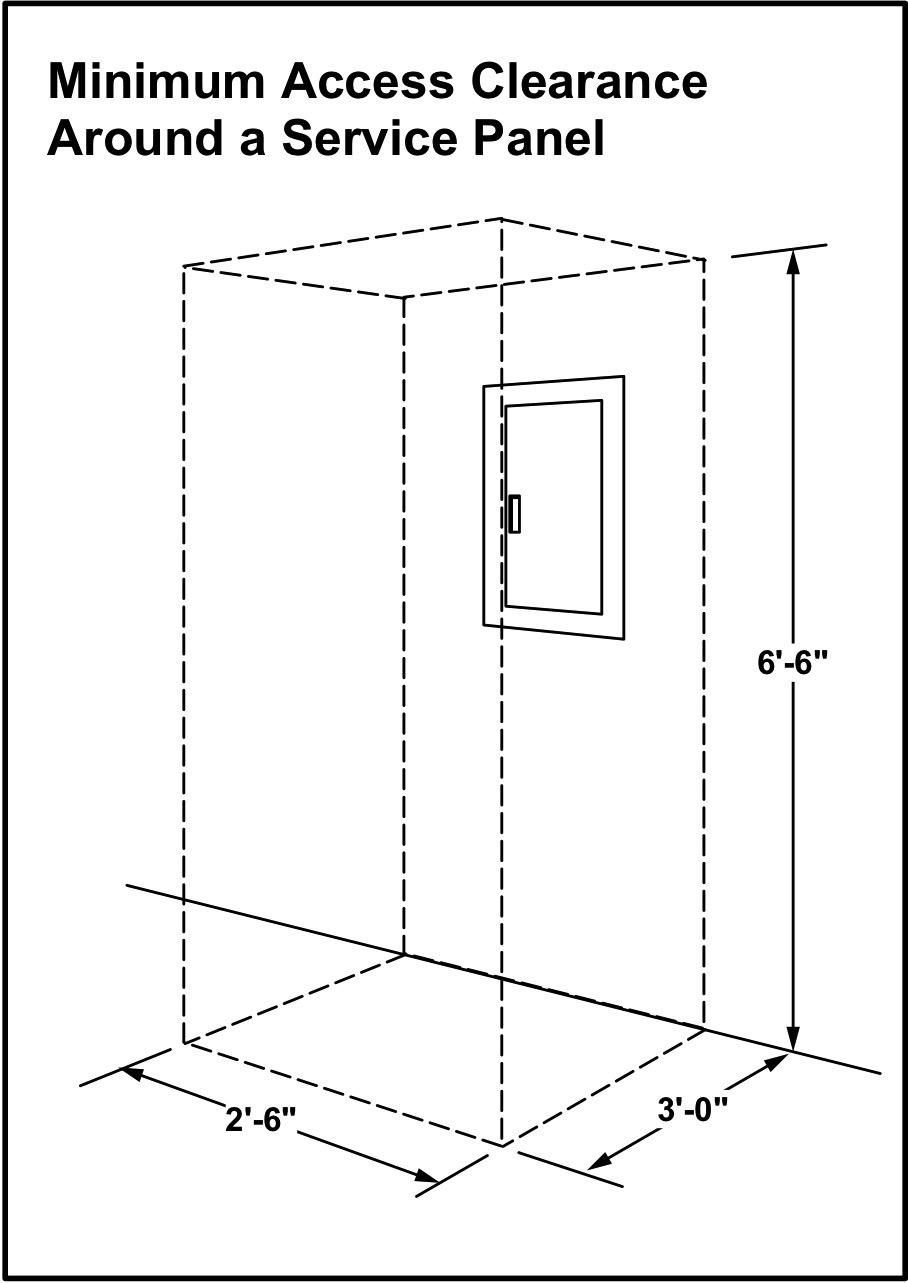

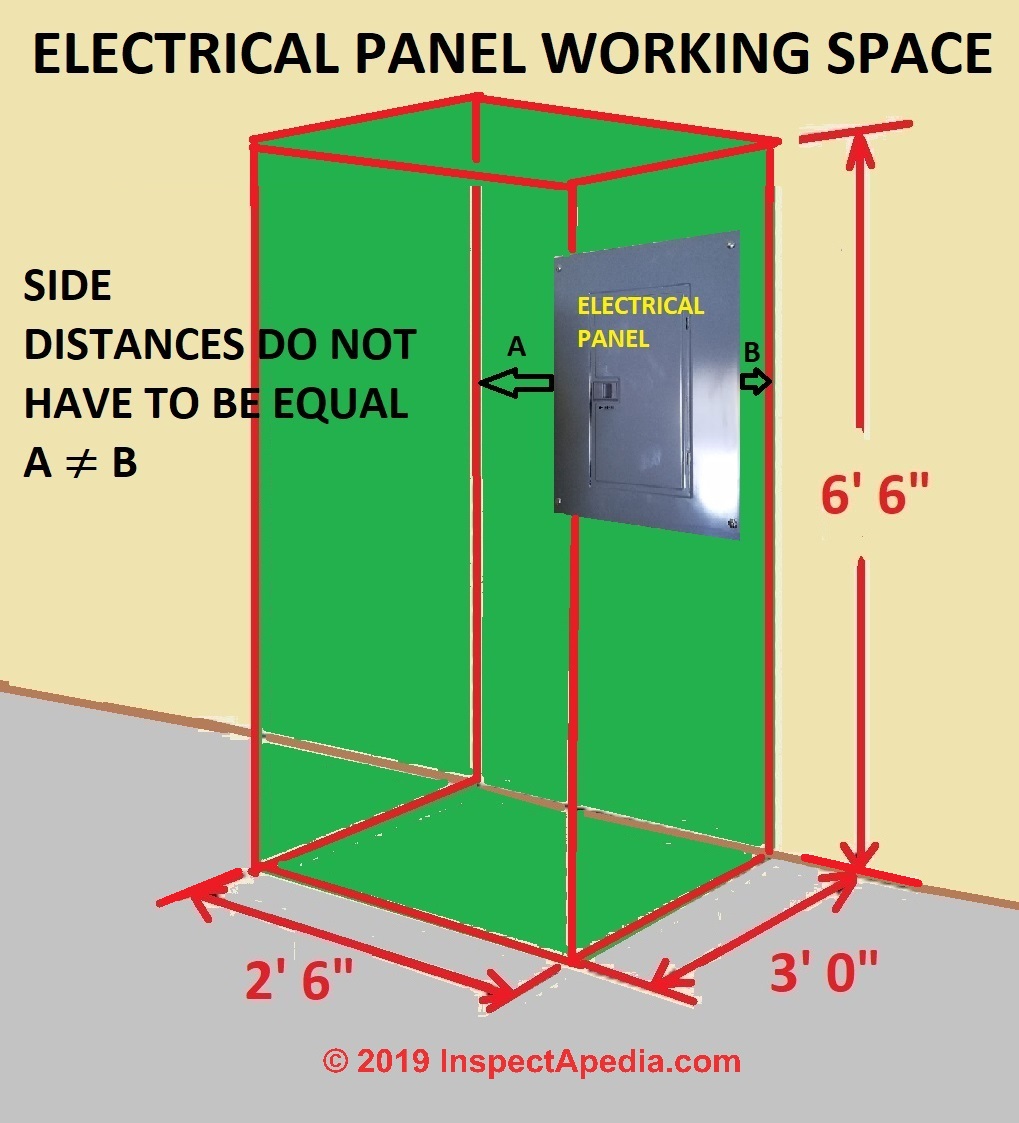

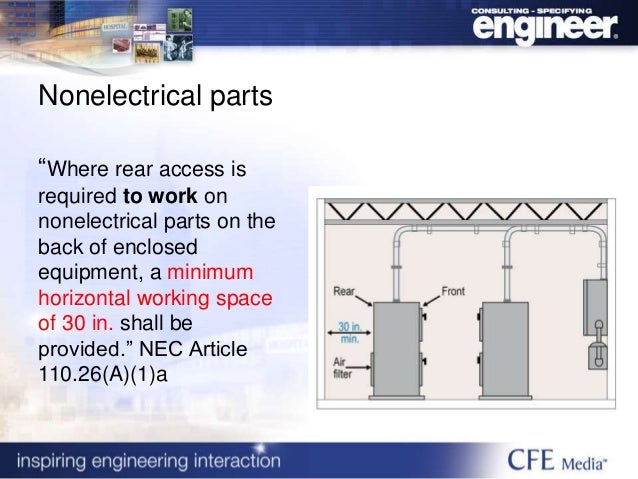

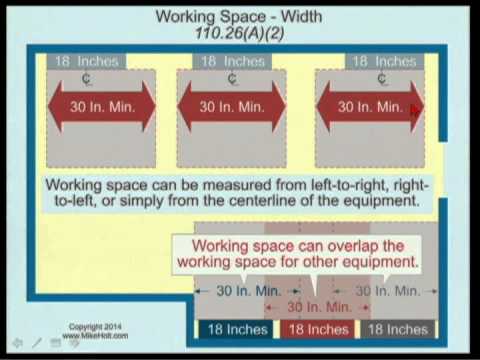

NEC (A) (2) states that "the width of the working space in front of the electrical equipment shall be the width of the equipment or 762 mm (30 in), whichever is greater" In addition, this work space shall permit at least a 90degree opening of the panelboard doorThis requirement first appeared in the 1987 NEC Height of working space Sec (a)(3)(e) As a general rule, you must maintain a minimum headroom clearance of 6 ft from the floor or platform up to any overhead obstruction This workspace is mandatory and applies to service equipment, switchboards, panelboards, and motor control centersRe NEC / Equipment in Outdoor Enclosures In my opinion per (A)(1) depth of working space is from the exterior of the enclosure if the equipment is an industrial control panel per 4092 or a motor control center

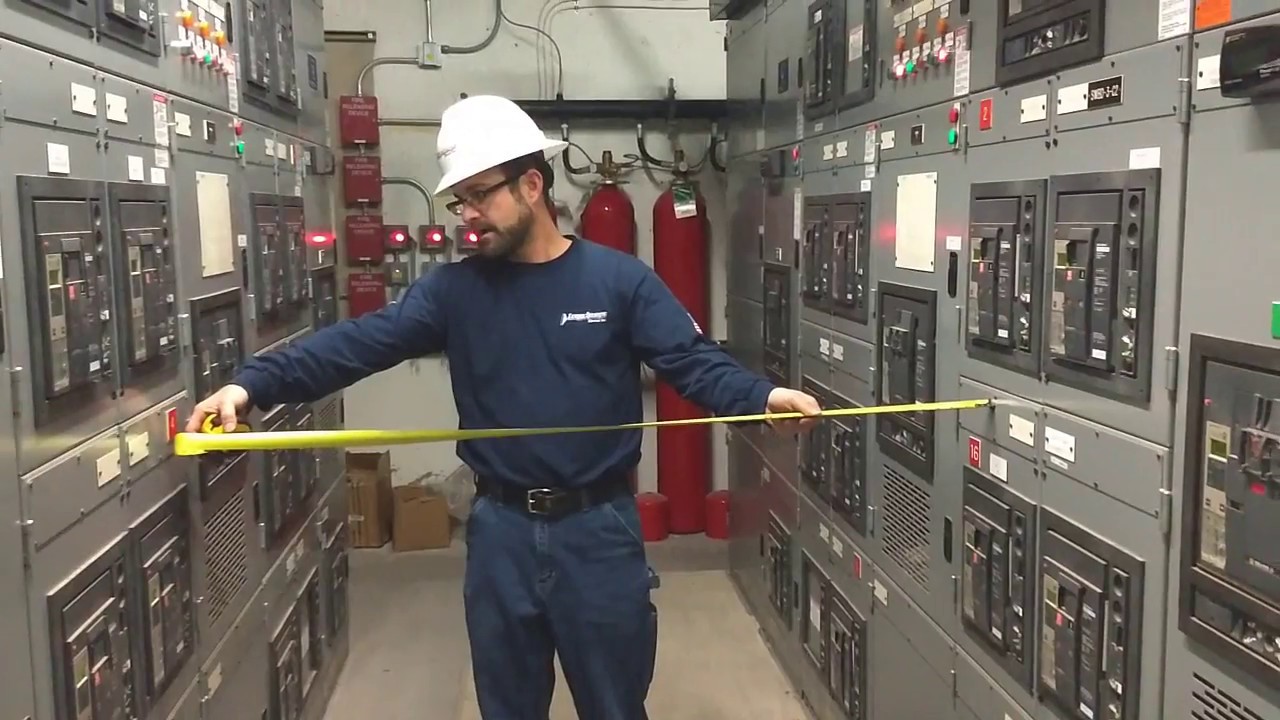

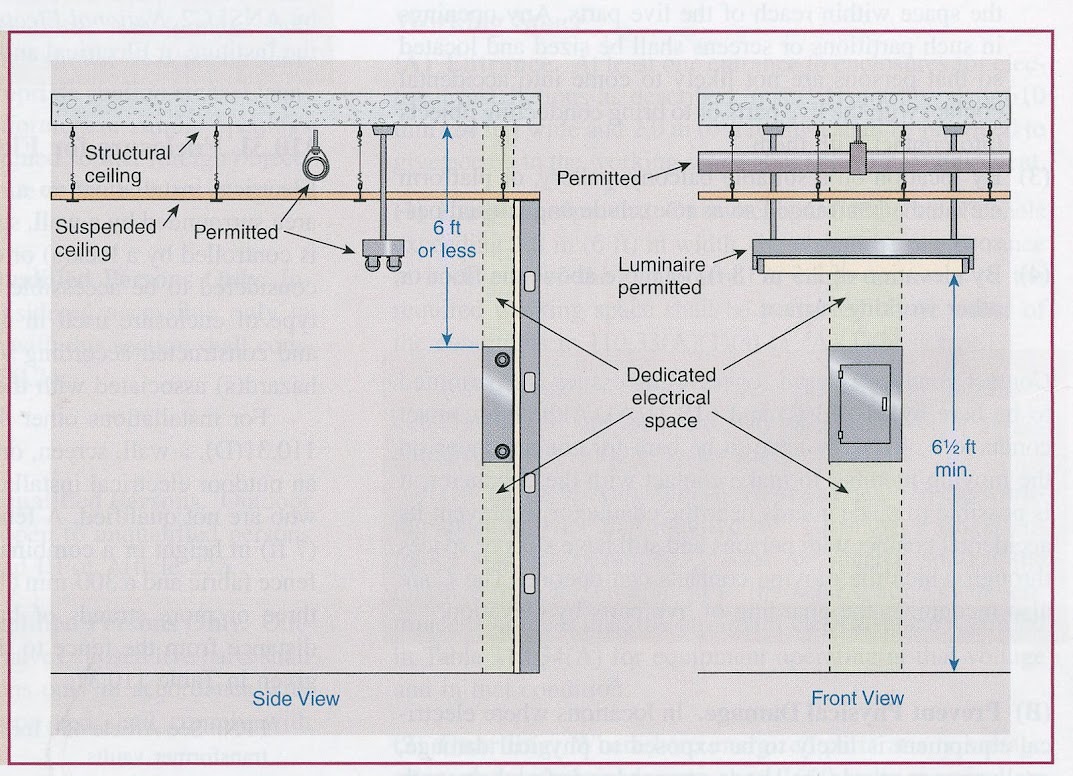

In the NEC, working space requirements are found primarily in Article 110 NEC applies to electrical equipment operating at 600 volts or less The primary requirement is that both access and working space must be provided and maintained for all electrical equipment (Photo 1)NEC (C) Entrance to Working Space (2) Large Equipment For equipment rated 10 amperes or more that contains overcurrent devices, switching devices, or control devices, there shall be one entrance to the required working space not less than 610 mm (24 in) wide and m (6 1/ 2 ft) high at each end of the working spaceIndoor installations shall comply with (E) (1)(a) through (E)(1)(d) (a) Dedicated Electrical Space The space equal to the width and depth of the equipment and extending from the floor to a height of 18 m (6 ft) above the equipment or to the structural ceiling, whi chever is lower, shall be dedicated to the electrical installation

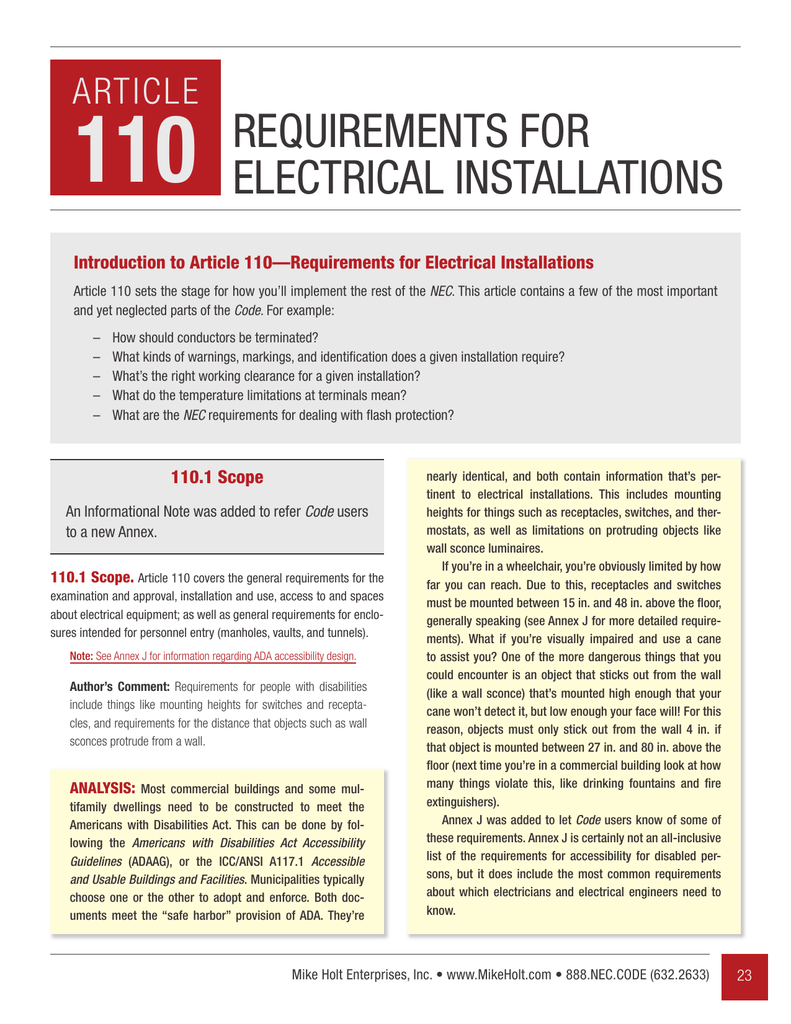

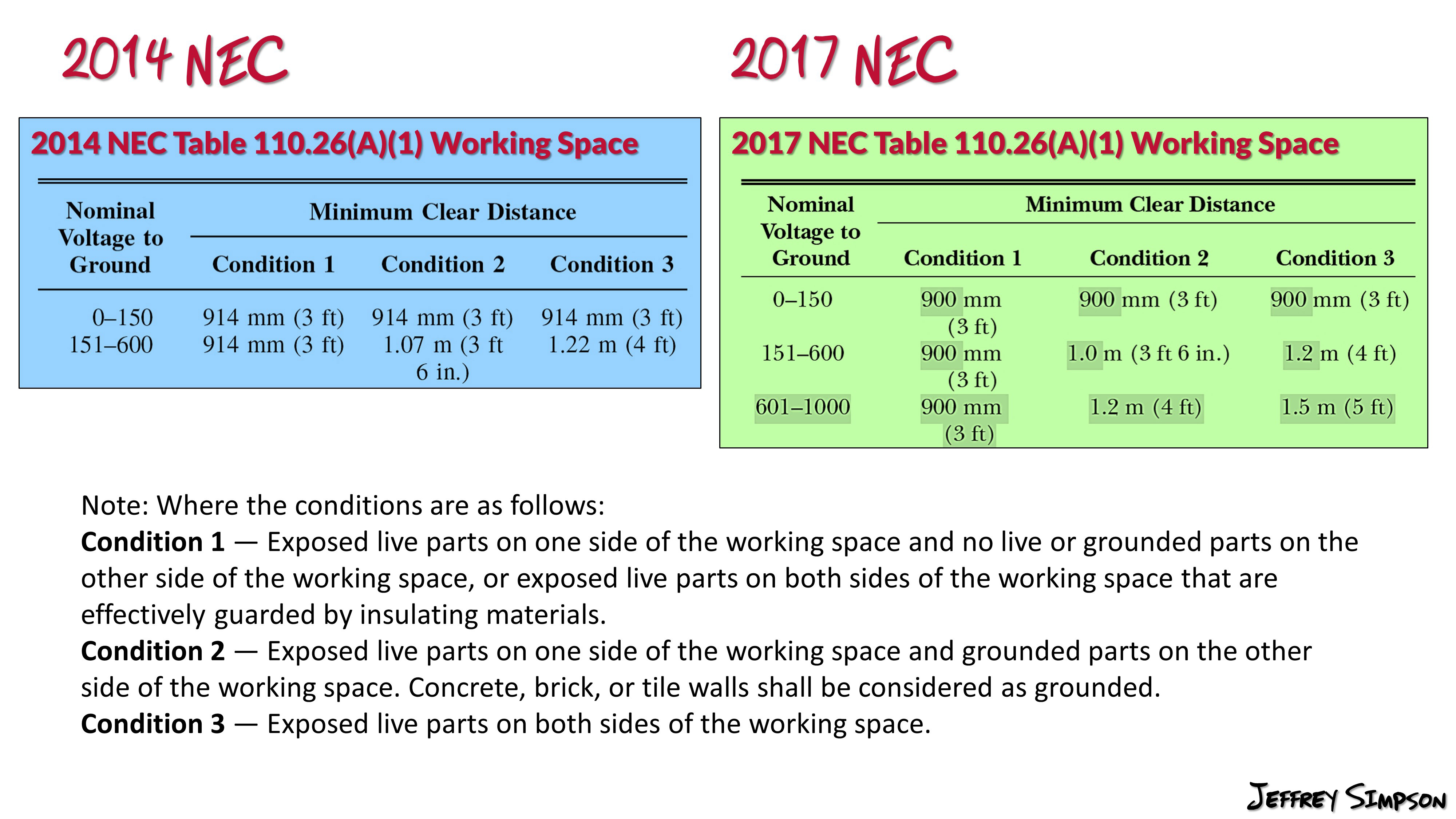

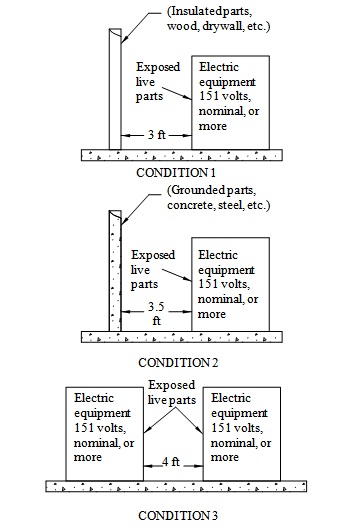

Egress and working space for rooms containing electrical overcurrent devices, switching devices, or control devices shall be in compliance with the International Fire Code and Section of NFPA 70 Background 15 IFC 6053 Working space and clearance A working space ofnot less than 30 inches (762 mm) in width, 36Workspace If equipment may require examination, adjustment, servicing, or maintenance while energized, you must install it in a workspace in accordance with items (1), (2), and (3) of (A) The phrase "while energized" is the root of many debatesTable (A)(1) Working Spaces Minimum Clear Distance Nominal Voltage to Ground Condition 1 Condition 2 Condition 3 0–150 900 mm(3 ft) 900 mm (3 ft) 900 mm (3 ft) 151–600 900 mm (3 ft) 11 m (3?

Www Mikeholt Com Instructor2 Img Product Pdf 17bk 1474 Sample Pdf

How Much Working Space Is Enough Ec M

To be on the safe side, the working space and space around electrical equipment should always be clear per (A), if possible As a basic rule, there should be at least 3 feet of space in front of all equipment with a 30 inch width as well as 6½ feet of headroom spaceFt) 12 m (4 ft)Reference National Electrical Code (NEC) Table (A)(1)) Condition 1—Exposed live parts on one side of the working space and no live or grounded parts, including concrete, brick, or tile walls are on the other side of the working space Condition 2—Exposed live parts on one side of the working space and grounded parts, including

Q Tbn And9gctpiwwoit00 Yme52xow2nfs7two1qce9l3pgrd6zhy3 Gtn7bz Usqp Cau

Adequate Workspace Keeps Electricians Safe Ec M

If you have a room that meets the above requirements, (C) (2) states that these electrical rooms must have an entrance/egress that is at least 24 inches wide and 65 feet tall at EACH end of the working space Working space requirements appear in Table (A) (1)The clear working space that is required by the first sentence as described in (A) may be eliminated only where examination, adjustment, servicing and maintenance are not "likely" to occur when energized exposed live parts, etc, are present" , 0649 PM #2(f)(1)(a) The dedicated space above equipment is now defined as a space extending from the floor to a height of 6 feet above the equipment or to the structural ceiling whichever is lower No piping, ducts, or equipment foreign to the electrical installation shall be installed in this space Got that Let's Go!

Www Ltrc Lsu Edu Ltc 11 Pdf National electric code clear workspace requirements Pdf

5 Nec Questions Based On The 14 Nec By Mike Holt Texas Electrical Excel

NEC 14 Article (B) Clear Spaces Working space required by this section shall not be used for storage When normally enclosed live parts are exposed for inspection or servicing, the working space, if in a passageway or general open space, shall be suitably guardedIn the NEC, working space requirements are found primarily in Article 110 NEC applies to electrical equipment operating at 600 volts or less The primary requirement is that both access and working space must be provided and maintained for all electrical equipment (Photo 1)The NEC requires one means of access and entrance to the working space where the workspace is doubled per Table (a), based on conditions 1, 2, or 3 With the workspace doubled in front of the equipment, a worker can move back out of the endangered workspace and exit along the length of the equipment

Solved E Tom Jones S Office 13 Match Up The Nec Se Ctio Chegg Com

Nec Working Clearance Youtube

11 Code Language (C)(3) Personnel Doors Where equipment rated 10 A or more that contains overcurrent devices, switching devices, or control devices is installed and there is a personnel door(s) intended for entrance to and egress from the working space less than 76 m (25 ft) from the nearest edge of the working space, the door(s) shall open in the direction of egress and beAnalysis Section (A) (3) describes the height of the working space and allows for electrical equipment to intrude into the working space for a maximum depth of 6" This can often be seen in equipment rooms that have a wireway protruding outward above or below a panelboardThe working space, which is measured from the enclosure front, must not be less than the distances contained in Table (A) (1) If you have grounded metal parts on the other side of the working space, you would need 3½ feet

Oshpd Ca Gov Document Seminar Electrical

Www Rockymountainpower Net Content Dam Pcorp Documents En Pp Rmp Electric Service Requirements Esr Ch4 Pdf

Only qualified electricians are permitted to perform maintenance work NEC article (A) ( 1) condition 3 states that exposed live parts on both sides of the working space require minimum clear distance of 4ft NEC does not explain the dead front panel working space requirements between panelsIn the 17 NEC, the basic rule in Section (C) (2) required an entry/exit at each end of the working space for large equipment when both of the following two circumstances were present Electrical equipment was rated 10 amps or more and contained overcurrent devices, switching devices, or control devices andNEC Table (A) (1) provides the minimum required work space depth for electrical equipment rated volts (to ground) that is likely to be examined or worked on while energized

Working Space Code Corner

Nec Article 110 Guide 11 Holt Nec Article 110 Guide 11 Holt Docsity

Article 110 sets the stage for how you'll implement the rest of the NEC This article contains a few of the most important and yet neglected parts of the Code For example in accordance with industry accepted safe work practice standards Note 1 NFPA 70E, Standard for Electrical Safety in the Workplace, proArticle Requires that sufficient access and working space shall be provided and maintained around all electrical equipment to permit ready and safe operation and mainte nance of such equipmentRE NEC Workig Clearance Requirements rcw retired EE (Electrical) 7 Jun 12 17 My interpretation is that working space depth is only doubled if there is only one egress from the space

Www Ltrc Lsu Edu Ltc 11 Pdf National electric code clear workspace requirements Pdf

Minimum Clearance Around Electrical Panels Carrying 600 Volts Or Less Mysafetysign Blog

The working space is defined in all three dimensions depth, width, and height Some of the working space requirements found in Section (NEC05) include (A) Working Space Working space for equipment operating at 600 volts, nominal, or less to ground and likely to require examination, adjustment, servicing, or maintenance whileNEC Article Electrical Room "Basics" Electrical Equipment Rated at 1,000 V or More, Article #3 of 3 April 2, 19 Dear Colleague To recap Article #1 from March 5th and as required by OSHA, NFPA and the NEC "working space around electrical enclosures or equipment shall be adequate for conducting all anticipated maintenance andThe purpose for the National Electrical Code is to provide a safe installation, but Article 110 is perhaps focused a little more on providing an installation that is safe for the installer and maintenance electrician, so time spent in

Chapter 34 General Requirements 15 Irc Portion Of The 18 Ct State Building Code Upcodes

Where Can Panelboards And Load Centers Be Located In My Building Wgi

In the NEC, the language in for working space about electrical equipment rated over 1000 volts was revised to align with similar requirements in Section for installations rated 1000 volts or less The previous code language allowed for the working space to be either 6 ½ feet high or no less than 3 feet wideNEC (A) (2) states that "the width of the working space in front of the electrical equipment shall be the width of the equipment or 762 mm (30 in), whichever is greater" In addition, this work space shall permit at least a 90degree opening of the panelboard doorEXHIBIT A working space with one entrance, which is permitted if the working space required by (A) is doubled see Table (A)(1) for permitted dimensions of X Where the entrance(s) to the working space is through a door, each door must comply with the requirements for swinging open in the direction of egress and

Requirements For Electrical Installations Pdf Free Download

General Installation Requirements Part Xxxv Article 110 Electrical Contractor Magazine

(A) Working Space Working space for equipment operating at 600 volts, nominal, or less, to ground and likely to require examination, adjustment, servicing, or maintenance while energized shall comply with the dimensions of (A) (1), (A) (2), and (A) (3) or as required or permitted elsewhere in this CodeIf you have a room that meets the above requirements, (C) (2) states that these electrical rooms must have an entrance/egress that is at least 24 inches wide and 65 feet tall at EACH end of the working space Working space requirements appear in Table (A) (1)Indoor installations shall comply with (E) (1)(a) through (E)(1)(d) (a) Dedicated Electrical Space The space equal to the width and depth of the equipment and extending from the floor to a height of 18 m (6 ft) above the equipment or to the structural ceiling, whi chever is lower, shall be dedicated to the electrical installation

Entrances To And From Electrical Equipment Rooms Pdf Free Download

Working Clearance Electrician Talk

The national electric code • nec • adopted by the louisiana legislature as law • not a design manual • is a minimum standard nec article working space shall be provided and maintained about all electric equipment likely to require while energized working space shall beIf you read Section (NEC05) you will observe that the disconnecting means requires a minimum amount of working space The working space is defined in all three dimensions depth, width, and height Some of the working space requirements found in Section (NEC05) includeConsidering that, there must still be amicable working space to work on equipment, including the replacement of components and the disassembly and removal of cover panels and doors as required by

Electrical Panel Equipment Working Space Clearance Distances U S Nec Article 110 26

Nec Code Changes Page 8

Width of working space around electrical equipment NEC (A) (2) Working space around electrical equipment must be as wide as the equipment or 30 inches, whichever is greater Height of working space around electrical equipment NEC (A) (3) For installations built before August 13, 07, the height of the working space must be 625 ftSection of the National Electrical Code (NEC) requires specific minimums for working space around electrical equipment Section is divided into six subsections, and some of them contain even more subsectionsWorking space for equipment shall be provided and maintained per subsection (A) to permit ready and safe operation of such equipment The placement of bollards within working space, even if they are removable is prohibited, since they don't permit ready access to the equipment

Oshpd Ca Gov Document Seminar Electrical

Entrance To And Egress From Working Spaces Part 1 Or 2

The minimum width of the working space is 30 in or the width of the equipment, whichever is greater, and all doors or panels must be able to open to 90 degrees or more This is the same as the general requirement found in (A) (2)NEC article (A) (1) condition 3 states that exposed live parts on both sides of the working space require minimum clear distance of 4ft NEC does not explain the dead front panel working space requirements between panels Under all circumstances, there are no live parts exposed to persons entering the electrical roomReference National Electrical Code (NEC) Table (A)(1)) Condition 1—Exposed live parts on one side of the working space and no live or grounded parts, including concrete, brick, or tile walls are on the other side of the working space Condition 2—Exposed live parts on one side of the working space and grounded parts, including

Working Space For Electrical Equipment Iaei Magazine

Working Space Requirements For Electrical Panelboards Iaei Magazine

In order to create safe working conditions, OSHA and the NEC provide working space requirements that vary according to the hazards involved with the installation and equipment The NEC starts by stating the space must be sufficient for "ready and safe operation and maintenance" of electrical equipmentThe 11 NEC revises (A) (3) to include all of the height requirements found in and adds a new exception for meters in meter sockets The height of the working space in front of equipment can't be less than 6½ ft, measured from the grade, floor, platform, or the equipment height (whichever is greater), as shown in Fig 4

General Installation Requirements Part Xxxiii Electrical Contractor Magazine

Subpanel Working Clearance Contractor Talk Professional Construction And Remodeling Forum

Where Can Panelboards And Load Centers Be Located In My Building Wgi

Sample Pages

Q Tbn And9gctsnrn4d3opm Knkr8tfd Qxhu12j5hu4ee0 Edqtbyyeq2ekfh Usqp Cau

Www Mikeholt Com Instructor2 Img Product Pdf 11nec101 1076 Sample Pdf

Nec Code Changes Update 8 Hours

Where Can I Move My Electric Panel Home Improvement Stack Exchange

Working Space For Electrical Equipment Iaei Magazine

Www Mikeholt Com Instructor2 Img Product Pdf 11nec101 1076 Sample Pdf

Panel Clearances Electrician Talk

Doe Handbook Electrical Safety General Requirements Rf Cafe

Http Www Teces Org Docs 12 Pdf

Www Mecknc Gov Luesa Codeenforcement Documents 19 electrical code academy meetings Pdf

Consulting Specifying Engineer Reviewing Analyzing Nec 14 Changes

Q Tbn And9gcqkkcyyfzdwu78lzw9uw5uk5tgqnn1j93hjfqj2 2myghfchgsv Usqp Cau

Http Www Teces Org Docs 12 Pdf

Code Changes 110 26 A 3 Working Ryan Jackson Electrical Training Facebook

Electrical Panel Equipment Working Space Clearance Distances U S Nec Article 110 26

Table 110 26 A 1 Working Spaces

When Did The Requirement For Clearance In Front Of An Electrical Panel Become Code

Www Mikeholt Com Instructor2 Img Product Pdf 11nec101 1076 Sample Pdf

Spaces About Electrical Equipment Nec Violation Example Carelient

Www Mikeholt Com Instructor2 Img Product Pdf 11nec101 1076 Sample Pdf

General Installation Requirements Part Xxxv Article 110 Electrical Contractor Magazine

110 26 E 2 Dedicated Equipment Space Outdoors

Inspectionnews Home Inspection

Electrical Panel Equipment Working Space Clearance Distances U S Nec Article 110 26

Inspectionnews Home Inspection

Panel Clearances Electrician Talk

Www Mikeholt Com Instructor2 Img Product Pdf 11nec101 1076 Sample Pdf

Consulting Specifying Engineer Integrated Design Of Electrical Rooms

110 32 Workspace About Equipment

Proposed Changes Revisions To The 17 National Electrical Code C

General Installation Requirements Part Xxxiii Electrical Contractor Magazine

Adequate Workspace Keeps Electricians Safe Ec M

110 26 A 4 Limited Access

Entrance To And Egress From Working Spaces Part 1 Or 2

Spacing For Manual Transfer Switch Diy Home Improvement Forum

Working Space Code Corner

Q Tbn And9gcqdt2hrdjclpsxkyqeef Ujydyrchsmjfxu8lhuxflkpfjhsedr Usqp Cau

Electrical Equipment Working Clearances To Help Prevent A Flashy End Mead Hunt

Working Space Code Corner

General Installation Requirements Part Xxviii Electrical Contractor Magazine

Www Mikeholt Com Instructor2 Img Product Pdf 11nec101 1076 Sample Pdf

Www Mikeholt Com Instructor2 Img Product Pdf 11nec101 1076 Sample Pdf

Code Quandaries Ec M

General Requirements Of The Nec Ec M

Working Space About Electrical Equipment Nec 14 110 26 23min sec Youtube

Http Www Teces Org Docs 12 Pdf

How Much Working Space Is Enough Ec M

Http Www Teces Org Docs 443 Pdf

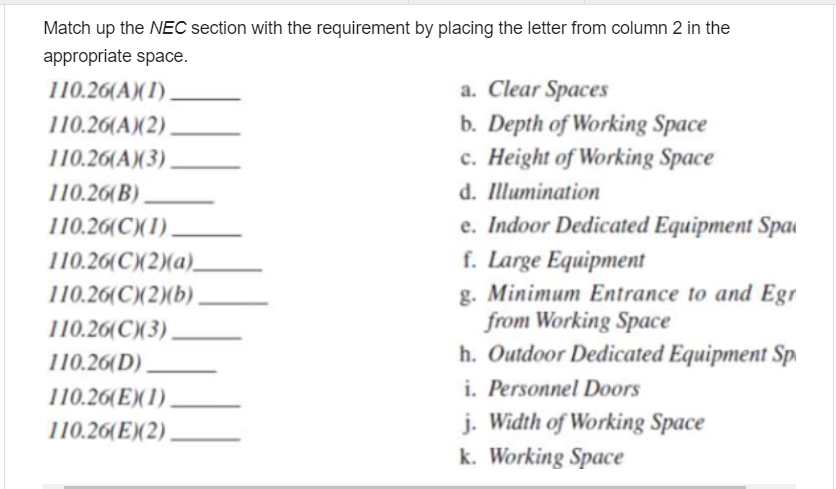

Solved Match Up The Nec Section With The Requirement By P Chegg Com

Requirements For Electrical Installations Pdf Free Download

Nec Article 110 Guide 11 Holt Nec Article 110 Guide 11 Holt Docsity

Electrical Systems Designing Electrical Rooms

Working Space Requirements For Electrical Panelboards Iaei Magazine

Adequate Clearance Electrical Inspections Internachi Forum

Www Mikeholt Com Instructor2 Img Product Pdf 11nec101 1076 Sample Pdf

Working Space Requirements For Electrical Panelboards Iaei Magazine

Www Ltrc Lsu Edu Ltc 11 Pdf National electric code clear workspace requirements Pdf

Adequate Workspace Keeps Electricians Safe Electrician Work Space Electrical Installation

National Electrical Code Nec Articles Tables And Data Mcgraw Hill Education Access Engineering

Oesc Test 1

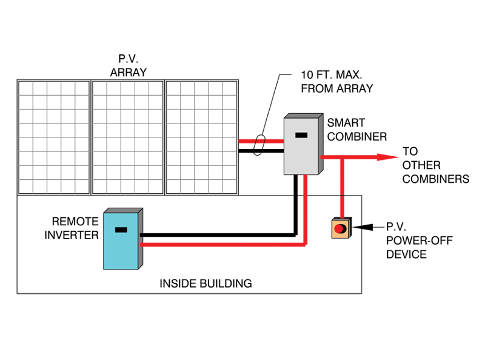

Seips Tech Tips Workspace Clearances For Solar Pv Systems Sei Professional Services

Electrical Code Requirements Photovoltaic System Electrical Wiring

Www Mikeholt Com Instructor2 Img Product Pdf 11nec101 1076 Sample Pdf

New Rules For Spaces With Limited Access Nec 17 110 26 A 4 Jade Learning

Oshpd Ca Gov Document Seminar Electrical

Code Changes 110 26 A 3 Working Ryan Jackson Electrical Training Facebook

Working Space For Electrical Equipment Iaei Magazine

Www Mikeholt Com Instructor2 Img Product Pdf 11nec101 1076 Sample Pdf

Electrician Live Understanding The Working Space And Dedicated Space Requirements In 110 26 Youtube

Working Space About Electrical Equipment Nec 14 110 26 23min sec Youtube

Working Space Requirements For Electrical Panelboards Iaei Magazine

General Installation Requirements Part Xxxiii Electrical Contractor Magazine

Working Space For Electrical Equipment Iaei Magazine

General Installation Requirements Part Xxvi Electrical Contractor Magazine